Most users who do DIY customization of mobile phone cases will use UV flatbed printers to print patterns directly on the case. The advantage is that full-color production can be performed without plate making, and it can be flexibly applied from order-to-order production, trial production to small batch on-demand production. But as competition in the market has intensified, prices have overwhelmed 2 yuan and become more and more homogeneous. If deep processing is used to increase the added value, talk about one of these processes, “bulging processing”.

Mobile phone shell bulge processing

It is a technology that stirs the special polyurethane resin liquid in a vacuum, then dangles and solidifies by surface tension, so as to make the surface appear spherical. Use bump processing technology instead of transparent ink printing to enhance the three-dimensional and glossy texture.

First various tools are needed in the process of ridge processing.

1, urethane liquid resin is prepared in a ratio of 1: 1.

The liquid resin used in the bumping process is divided into two types: a liquid resin body and a curing agent. Mix them in a 1: 1 ratio. Because the specific gravity is the same, it can be adjusted while weighing with an electronic scale. This time, a total of 50 g of urethane liquid resin was used in units of 25 g each time.

2.Vacuum stirring in a blender

The necessary amount of resin was transferred to a cup, placed on a lid for vacuum stirring, and then mounted on a stirrer. The air was agitated for 6 minutes while extracting air.

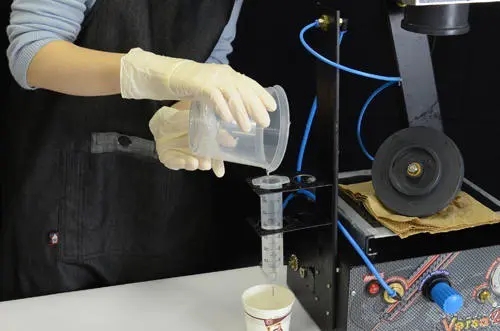

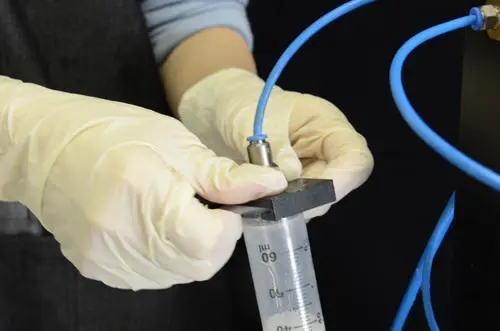

3. Move to the syringe and the installation is complete!

After the counter sounds, close the suction device, remove the plug cock, and remove the container. Carefully inject the liquid resin into a syringe for dripping liquid resin. In this case, in order to prevent liquid resin from leaking from the top of the syringe, place a container such as a paper cup in advance. If the cover of the connected compressor can be inserted securely, the preparation is complete!

4, the bulge processing is performed below!

Drop the liquid resin with a syringe. The working principle is: Press the plug-opening lever connected to the compressor, and the resin can flow out from the top of the syringe when air is fed in. The liquid resin is very viscous. When processing a mobile phone case, if two large pieces are dripped in advance, the resin will gradually spread and it will stop by itself when covering.

Please specify:Yescase Store » Mobile phone shell bulge processing technology