The difference between water sticker, painted and IMD process

The difference between IMD, painted and water paste

In recent years, IMD craft mobile phone cases have been very popular, but many customers have confused the water paste craft mobile phone cases, painted craft mobile phone cases with IMD craft mobile phone cases, and the price quality is also unclear! Here are the main differences between the three processes:

1. IMD process description:

IMD is a molding method that puts the printed film into a metal mold, injects the molding TPU into the metal mold, and joins the film, so that the printed film is integrated with the TPU and cured into a product. .

IMD Features:

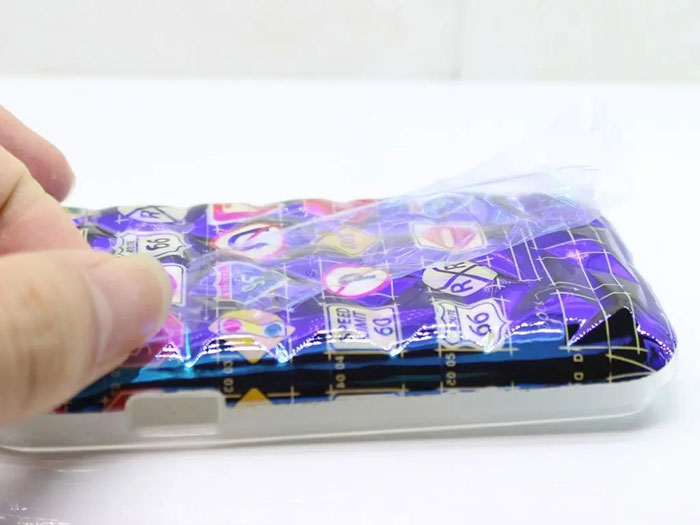

IMD is an internationally popular surface decoration technology. Because the pattern is in the middle of the sheet (the sheet is transparent) and TPU, there is no possibility of being scratched and rubbed off, and the color can be kept bright for a long time without fading. Product patterns can be high-definition highlights, or matte matte. When the product is in the customer’s hands, the protective film on the surface of the sheet is removed, the product is clearer and feels better.

Whether a layer of film is left on the surface is the biggest difference between the water paste process and the painted process.

2, the water paste process description:

Water sticker is a process that uses a film to transfer the pattern to the surface of the material. The specific method is to soak the water sticker in the water for about 1 minute to separate the film from the paper. The film is attached to the surface of the object with an ink layer. You can use the film The toughness allows the ink layer to be attached to the material of the mobile phone case, and then dried to remove the water and then sprayed with oil to increase the feel and gloss. The product pattern can be high-gloss or matte but is mainly determined by the sprayed oil and spray technology.

Water Sticker Features:

The production of water stickers takes a long time, mainly relying on artificial stickers, so the pattern positioning of each mobile phone case is not necessarily the same, and the surface needs to be sprayed with oil. Different oil and spray technologies are selected, and the processing costs are not the same. The quality varies and the prices vary.

Whether there is a pattern around the product (as shown above) is the biggest difference between the water paste process and the IMD process and the color painting process, and this is also the biggest advantage of the water paste.

3, the painting process description:

Color painting (also known as printing process): This is the simplest of the three processes. In simple terms, it is a color printer that is usually used to print patterns on mobile phone cases. Of course, its printer is very large. As shown below:

Painted Features:

The characteristic of this process is that there are no pattern restrictions. What patterns you want to print can be printed immediately and instantly. The flexibility is very high. The disadvantage is that you can only print the front pattern, as shown below:

This uneven surface can also be printed, as shown below:

The operation of color painting is simple, convenient to make, fast to ship, and relatively cheap in price. Because it is directly printed, the pattern will be worn over time. The pattern is relatively less clear than the IMD process. Generally, it is matt and high-gloss. It is necessary to inject fuel through reprocessing, but the cost increases accordingly.

Through the comparison of the above three processes, we find that in fact, no matter what kind of process, there are his advantages and disadvantages, and the one that suits his customers is the best.

In the past two years, the IMD process is very popular, and it is also the process with the largest export volume in the protective sleeve. But many customers confuse the painted shell with the IMD process shell, and say that the painted shell that can be approved for 3-4 yuan costs 7-9 yuan? Here we introduce these two processes:

IMD: It is a new technology that puts Film film in the injection mold to decorate the appearance surface of the mobile phone case. The pattern is printed on the PET film, and then placed in the injection molding machine to be fixed in the mold cavity for injection molding, so that the pattern remains synchronously and permanently on the surface of the shell. It has a smooth and beautiful appearance and permanent and clear printing. This is an incomparable advantage of traditional technologies such as painting / water transfer / 3D patterns! The surface of the product is wear-resistant and flower-resistant, and will not fade forever. (Also the most exported product in the hard shell)

Color painting: Use UV printer to directly arrange the pattern on the bottom case and print it. Compared with IMD case, the process is much simpler, so the price will be cheaper.

Transfer stickers are also called water stickers, watermarks, and watercolor printing. It is a new surface treatment process that can replace various processes such as pad printing, screen printing, painting, thermal transfer, and spray coating. The patterns are exquisite, with clear dots, Features fine tones, soft surface and stable performance. Water transfer film is a printing film used in the water coating process. Its use is often in the pattern effect of a large area, and it has a regular pattern.